Foam Core Stress-Skin Shell Method for Insul-Tanks

This

method

creates

two

very

thin

and

strong

shells

that

are

comprised

of

a

unique,

ultra

high-performance

cementitious

composite.

This

special

high-strength

coating

and

is

hand-applied

with

a

trowel

to

both

sides

of

2

inch

thick

extruded

polystyrene

insulation

panels

and

embedded

with

layers

of

fiberglass

grid

reinforcing

and

finished with a brush-on glaze of similar material.

The

rigid

blue

foam

panels

are

often

called

‘Dow

Board’

and

they

come

in

several

thickness

and

varieties

such

as

High-Load

Dow

Board

that

has

a

higher

compressive

strength

than

the

regular

15

psi

Dow

Board.

The

Insul-Tanks

use

2

inch

thick

regular

Dow

Board

that

comes

in

the

4

feet

by

8

feet

by

2

inch

sheets.

The

two,

very

thin,

surface

shells

transform

the

foam

into

very

rigid

and

damage

resistant

material

because

the

high-strength

composite

and

reinforcing

create a stress-skin, or structural sandwich, effect.

The

composite

wet

mix

plaster

and

the

finish

glaze

are

both

made

by

combining

special

additives

that

are

used

for

Ultra

High

Performance

Concrete

with

pre-bagged

polymer-modified

cement.

This

polymer-modified

cement

is

readily

available

in

Building

Materials

Supply

Outlets

that

carry

plaster

supplies.

It

is

used

as

a

base-coat

for

EIFS

(Exterior

Insulation

and

Finish

System)

as

is

the

special

fiberglass

mesh

that

is

used

with

it.

Typically

the

base

mix

and

glass

make

a

sturdy

shell

for

EIFS

but

adding

the

water-reducer/superplasticizer

called

Eucon

SPJ

and

a

refined

pozzolan

called

Micron

3,

greatly

reduces

the

porosity

and

increases

the

density

of

the

cement

based

shell

resulting

in

a

harder

and

more

chemically resistant shell.

Adhesive

Base

Coat

Mix:

This

usually

comes

in

50

#

bags

and

is

used

as

plaster

for

embedding

fiberglass

mesh

onto

foam

board

for

the

exterior

of

buildings.

It

is

called

adhesive

base-coat

because

it

adheres

the

fiberglass

reinforcing

to

the

foam

while

making

a

hard

protective

shell.

The

finish

system

that

goes

over

the

adhesive

base

coat

is

usually

a

sprayed

stucco

texture

of

rubberized

sand

to

make

a

nice

smooth

sandy

finish.

The

adhesive

base

coat

mix

is

a

true

polymer

modified

cement

that

consist

of

about

50

percent

Portland

Cement,

40

percent

fine

quartzite

sand

and

10

percent

dry

(high-solids)

acrylic

usually

an

acrylic

vinyl

acetate

co-polymer.

Some

common

brand

names

are

Dryvit

Primus

and

UltraKote.

They

come

in

50

pound

sacks

that

cost

between

24

and

35 dollars each. For this high strength version of this mix, it is necessary to only mix up a small 64 ounce batch.

Crack-Free

Fiber

Glass

Mesh

–

This

mesh

is

specially

engineered

for

a

cementitious

matrix

because

it

is

has

a

light

rubberized

coating

to

prevent

alkali

chemical

attack

on

the

fiberglass.

This

fiberglass

mesh

comes

in

150

feet rolls that are 38 inches to 48 inches wide and that cost between 85 and 125 dollars each.

The

fiberglass

mesh

is

cut

to

match

the

layouts,

the

planned

plaster

area

for

a

batch,

so

that

two

or

three

layers

will

be

used.

The

layout

is

drawn

onto

the

foam

with

a

marker.

The

layout

is

between

6

and

10

square

feet

and

will

use

the

mix

that

is

about

½

gallon.

An

additional

line

that

is

inset

one

inch

from

the

edges

of

the

layout

is

drawn

to

denote

the

overlap

area

to

the

adjoining

pieces.

On

the

overlap

area,

the

fiberglass

is

not

covered

with

extra

composite

material

or

a

glaze

so

the

overlap

can

be

seen

and

so

the

overlap

area

is

not

thicker

than

the

rest

of the shell.

Other Uses of this Foam Core Stress-Skin Shell Method

Besides

the

Insul-Tanks

this

basic

shell

method

can

be

used

for

many

things

where

a

durable,

water-proof

and

easy

to

shape

and

smooth

surface

is

desired.

The

insulation

really

helps

the

material

to

serve

other

important

purposes. Some of the other uses for this Foam Core Stress-Skin Method are:

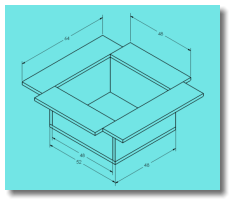

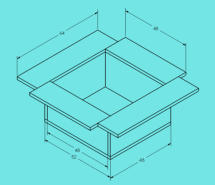

Cantilevered Countertops and Shelves

– The base material is easy to shape and sand. (Insert Image)

The

enhanced

shell

material

is

very

durable

and

easy

to

repair.

A

2

inch

shelf

can

be

fully

supported

from

one

side,

provided

it

is

bonding

with

the

same

material

as

a

backing

that

is

mounted

to

the

wall

or

a

self

supporting

unit that sits on the floor.

This

allows

more

open

designs

for

counters

such

as

counter

tops

that

do

not

need

cabinets

below

for

supports.

Open shelves can be placed below and above.

Self-supporting

Prefabbed

sections

can

be

brought

inside,

or

used

as

durable

outdoor

kitchen

elements

and

assembled

to

make

beautiful

counter

top

and

shelf

assemblies

transforming

a

bare

room

or

patio

into

a

functional

and

beautiful

kitchen

The

cantilevered

shelves

attach

to

the

backing

with

a

small

radius

instead

of

a

sharp

corner

so

it

does

not

dark,

recessed

and

dusty

corners

where

spiders

can

build

webs.

That

web-free

corner

combined

with

the

more

open

design

enabled

by

the

stress-skin

effect,

makes

the

kitchen

and

bathroom

designs

easy

to

clean and brings in a new element of simplicity to design that was not available before.

Bath

&

Shower

Details

–

The

material

is

well

suited

for

bathtubs,

showers

and

bathroom

sink

&

shelf

assemblies

the

same

as

the

kitchen.

Finishing

the

smooth

glaze

on

the

high-strength

composite

with

chlorinated

rubber paint makes for an easy to clean and durable surface.

Cabinets,

Doors

and

Windows

–

This

is

a

great

medium

for

making

decorative

doors

and

windows

that

have

complex

shapes.

For

making

hatch

designs

that

are

more

curvy

than

square

doors,

the

medium

allows

you

to

sand

precise

shapes

that

will

make

a

good

weather

seal.

You

can

make

conventional

doors

and

window

frame

designs as well, but the insulation here makes this medium better.

Surface

Paint

-

The

surface

shell

is

very

dense

and

hard

but

bonds

to

the

chlorinated

rubber

paint

better

than

other

cement

shells

such

as

swimming

pool

concrete.

This

is

because

the

sand

aggregate

in

the

enhanced

polymer-modified

mortar

mix

is

much

smaller

and

so

will

not

flake

away

or

weather

away

as

quickly.

The

harder

mix

allows

the

swimming

pool

paint

to

endure

warmer

temperatures

because

of

the

better

bond.

If

the

paint

does

show

signs

of

weathering

over

the

years,

a

fresh

coat

can

be

applied.

If

an

epoxy

paint

is

preferred

for

longevity,

the

composite

can

be

sanded

and

prepped

for

an

epoxy

paint,

that

will

endure

heat

better

and

is

what

is

typically

used

for

hot

tubs,

but

the

epoxy

paint

could

fade

in

the

sunlight

whereas

the

chlorinated

rubber

endures

ultra-violate

better.

The

chlorinated

rubber

swimming

pool

paint

may

last

longer

on

this

particular

composite

design,

even

though

epoxy

based

swimming

pool

paints

will

last

longer

on

conventional

concrete.

Both

are

good

options

but

on

this

shell,

it

is

easier

to

prepare

the

rubber

painted

surface

for

a

new

coating

of

epoxy

swimming

pool paint.

Installing

Hardware,

such

as

hinges

and

latches

-

Hinges

and

latches

bond

differently

to

this

medium

that

to

wood.

The

bond

is

more

durable

because

the

anchor

into

the

shell

material

on

the

surfaces

rather

than

in

the

middle.

The

pins

or

bolts

that

support

the

hinges

or

other

hardware

go

from

one

side

of

the

stress-skin

shell

to

the

other

and

anchor

to

the

plane

of

the

shell,

by

using

washers

that

are

layered

into

the

composite

and

fiberglass.

In

wood,

a

screw

will

rely

on

a

friction

bond

on

the

inside.

This

bond

can

loosen

over

time

as

repeat

strains

are

placed

on

the

screw

or

as

the

wood

shrinks

and

degrades

over

time.

Plastering

the

hardware

into

both

of

the

supporting

shell

makes

it

so

that

bending

strains

placed

on

the

hardware

will

not

weaken

the

connection.

This

is

because

the

strains

are

more

in-line

with

the

direction

of

tensile

and

compression

reinforcing

on

the

hardened

shell.

The

expected

deflection

caused

by

strong

bending

strains,

such

as

hanging

on

a

door

or

cabinet

door,

strains

strong

enough

to

damage

the

stress-skin

shell

surround

the

hardware,

are

not

likely

to

dislodge

the

hardware

because

the

pull-out

resistance,

the

twisting

resistance

are

all

fully

countered

better

than

the

breaking

resistance

around the hardware, meaning the stress-skin hull would break before the hardware pulled loose.

INSUL-TANKS